News

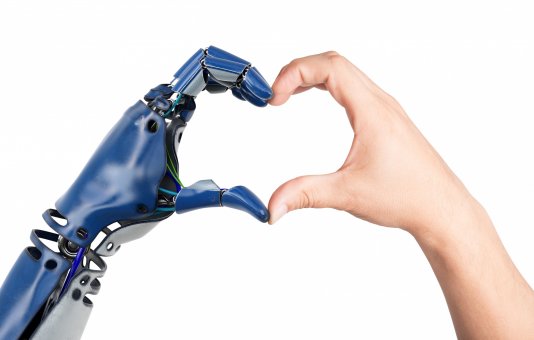

How do connectors help you navigate your way towards industry 5.0?

Automation and customisation all-in-one

Industry 4.0 has not yet been fully digested and yet we are all cautiously inching towards Industry 5.0, wondering what movement this will set in motion. There are various opinions in this respect, and yet they all have a common thread. Industry 5.0 is changing tack when it comes to the focus of change. Whereas Industry 4.0 was all about intelligent and cost-efficient production chains, i.e. the internal organisation, Industry 5.0 will be entirely focused on customisation, the customer, creating automated customisation processes and products for every customer. In other words, automation and customisation all in one.

ENHANCING THE CUSTOMER EXPERIENCE

To a certain extent, Industry 4.0 took its eye off the customer. On the other hand, we could say that it paved the way for Industry 5.0. Thanks to investments in automating production processes and machine interconnectivity, manufacturers are now much better placed to produce customised products. The efficiency gains made in their production processes now allow for more flexibility.

In concrete terms, this means that the two elements going hand in hand ensures that machine builders in the future will be able to produce exactly according to the customer's wishes, without extra costs or delays in delivery, with the predetermined aim of enhancing the customer experience.

FLEXIBILITY AND MODULAR DESIGN CRITICAL FOR SUCCESS

In the automotive industry, customisation has been a hot topic for some time, and front-runners such as Mini and Audi are showing how it is possible to manage a complex production system that offers extensive options, based on the individual preferences of the customer.

Manufacturers and suppliers of components such as connectors and power supplies will also have to pull their weight in order to meet the customisation shift in Industry 5.0. As a distributor, we see in particular that flexibility and modular design are critical for success.

THE INDUSTRY 5.0 APPROACH OF HUMMEL AND ILME

A&C Solutions works with manufacturers of industrial connectors, who are each preparing for the 5.0 era in their own way. Our German manufacturer Hummel is staking everything on modular design with its robust M16, M23 and M40 connectors, in order to be the all-round genius in the field of industrial connectors. For example, all Hummel housings can be combined with a range of different inserts. For customers, this means that every conceivable number of contacts can be created using only one type of connector as a basis.

ENDLESS CHOICE

A nice example of this is the successful M23 range. Hummel offers connector solutions for signal, power, and industrial Ethernet. But also hybrid connectors with a combination of power, data and Ethernet, or a combination of PoE, to transport data at high (gigabit) speeds.

For applications in the signal segment alone, there are 26 models in total for different types of connectors. These in turn can also be equipped with ten different inserts. In addition, male and female connectors are all interchangeable. Naturally, this offers endless choice for the customer.

INTERCHANGEABLE WITH SPEEDTEC

Hummel also extends flexibility to the connectivity of its connectors. Within its own brand, Hummel offers screw connectors as well as connectors with the patented, quick release TWILOCK lock system. And beyond this, a large portion of the M23 and M40 signal and power connectors are perfectly interchangeable with the well-known Speedtec locking system, designated by Hummel as TWILOCK-S.

OPEN CONNECTOR SYSTEM ILME MIXO

Our manufacturer Ilme, who primarily develops products based on market and customer needs, is also increasingly responding to customisation possibilities for the customer. The result is the MIXO modular system. This open connector system, with more than 40 modules, offers the customer the possibility to customise their connector with their preferred Ilme housing. The customer can combine up to 6 modules of power, (optical) signal, data transmission and air into one Ilme connector. This is done quickly and easily. The modules are arranged side by side to form one single block. This block is then installed in a metal frame and locked with special tabs. The connector is then installed in the housing. A technically simple solution for Ilme production-wise, which results in a tailor-made, high-quality, robust connector for all demanding applications.

MARKET-ORIENTATED APPROACH OF MANUFACTURER AND DISTRIBUTOR IS KEY FOCUS

It is reassuring to see that the path taken by top tier manufacturers such as Hummel and Ilme is clearly in line with the next-level development of the industry. The basis is there. Now it is vital to keep a close eye on the connection with the market and customers, so that the development of these modular systems is actually based on the needs of the customer. And this is precisely the role that we, as a distributor, have to play. And we are going to do our very best in that respect.

Would you like advice on which industrial connectors can be fully customised for your application?